EMS Calibration

Vehicle

Calibration

Target vehicle

- Gasoline

- Diesel

- Hybrid

- EV

Calibration

- Emission

- OBD-II

- Driveability

- After treatment system

Emission calibration

- SULEV, EURO 6 / 7, China 6 and Tier 4 (Industrial)

- Emission related hardware and component selection

- Optimization of logic and calibration for leaner cold fueling

- UREA-SCR application

- DPF calibration

Drivability calibration

- Optimum calibration for high drivability index fuel

- Logic development for high drivability index fuel

- Drivability calibration over -30 ˜ 50。... ambient temperature

OBD-II calibration

- OBD-II, EOBD and KOBD regulation

Vehicle benchmarking

- Emission related hardware, logic and calibration

- Fuel economy related hardware, logic and calibration

- Drivability related logic and calibration

Fuel economy analysis

- Energy Flow-Down Method

Development of advanced fuel economy system and logic

Catalyst bench aging and vehicle durability cycle development corelated with in-use DF

Gasoline

SULEV application

Fast light-off control

-

H / W side

- Place the catalyst as close as possible to exhaust manifold

- Increase catalyst cell density

-

Calibration side to increase heat flux

- Increase Idle engine speed

- Spark timing calibration

- Waste-gate position open control

Reduce engine-out raw emissions

: optimum catalyst heating point and cold start

- Intake / exhaust VVT control

-

Injection strategy calibration

: SOI, EOI, fuel pressure, split injection calibration

NOx conversion efficiency increase

- Fuel cut off condition calibration

- Catalyst purge calibration to increase NOx conversion efficiency

- Lambda control calibration with downstream O2 sensor feedback

Gasoline

particulate

filter control

GPF model calibration

- DP soot mass with clean filter model

- Engine out soot model

- Soot burning rate model

- GPF temperature model

GPF control

-

Passive / active regeneration control

(Lambda, temperature control) - Fuel cut off conditon calibration during regeneration

- Soot mass validation (model vs actual mass)

- Soot burning efficiency test

- Service regeneration strategy

- GPF regeneration strategy (duration, coordinator)

- GPF OBD (efficiency) strategy

GPF validation test

-

GPF failure check through uncontrolled burning test (DTI, DTO)

: CT scanning confirmed - Environment test (cold, hot, altitude)

- Ash calibration with fleet test

Diesel SCR control

SCR model calibration

- Raw NOx, NO / NO2 ratio modeling

- NOx conversion efficiency modeling

- NH3 loading / slip modeling

- SCR temperature model

- SCR efficiency model

SCR Control

- Heat-up

- NH3 loading target

- Urea dosing schedule

- SCR defrost calibration in cold condition

- Strategy for improvement of emission(RDE, WLTC, NEDC, etc.)

- SCR OBD strategy(efficiency, incorrect urea, consumption, etc.)

SCR validation test

- Environment test(cold, hot, altitude)

- Validation of model accuracy

- Robustness of NOx conversion efficiency in real driving

Diesel

particulate

filter control

DPF model calibration

- DP soot mass with clean filter model

- Engine out soot model

- Soot burning rate model

- DPF temperature model

DPF control

- Heat-up / active regeneration control (air control, post injection control)

- Open & closed loop temperature control

- Transient conditon check and calibration

- Soot mass validation (model vs actual mass)

- Soot burning efficiency test

- Service regeneration strategy

- DPF regeneration strategy (duration, coordinator)

- DPF OBD (PM sensor, efficiency) strategy

DPF validation test

-

DPF failure check through uncontrolled burning test (DTI, DTO)

: CT scanning confirmed - Environment test (cold, hot, altitude)

- Oil dilution & ash check with fleet test

Diesel

EURO 7 / China 6

Additional challenge for better fuel consumption

-

Thermal management

- Integrated thermal management 3-way valve control(block, radiator, heater)

- Split cooling circuit

- Optimized temperature of each part

-

Weight reduction

- Aluminum cylinder block

-

Friction reduction

- Piston & ring design optimization

- Crankshaft balance weight optimization

- Variable oil pump integrated with vacuum pump

- Timing belt instead of chain system

- Camcarrier-camshaft module

- Crank offset

- Roller rocker arm

- Switchable water pump or electrically controlled thermostat

After treatment system

- SCR system will be in multiple locations and the total size will be larger

- Urea injection will be multi-point injection.

- DPF would not need active regeneration any more, only passive type would be enough.

- Electrically heated catalyst could be used for cold start emission.

Combustion system

- With enhanced SCR system, engine developmint could be focused only on better thermal efficiency and on reducing PM, no longer on reducing NOx emission as before.

- Compression ratio would be raised to around 18 from current 15~16.

- EGR would be used limitedly or the system even may be deleted.

- High swirl would be required less than before, therefore port could be optimized for more flow.

Electrification

- 48V mild hybrid system will used.(P0~P2)

- EHC could be effective by 48V system

Fuel Economy

Analysis

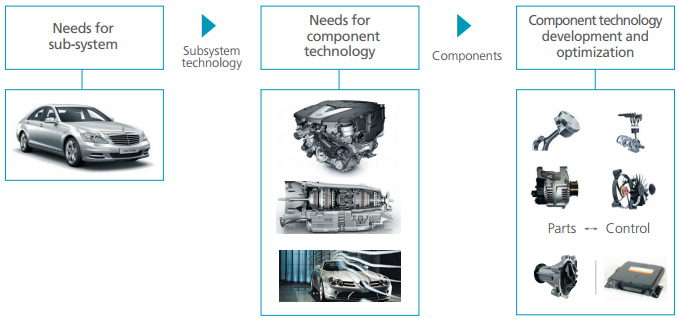

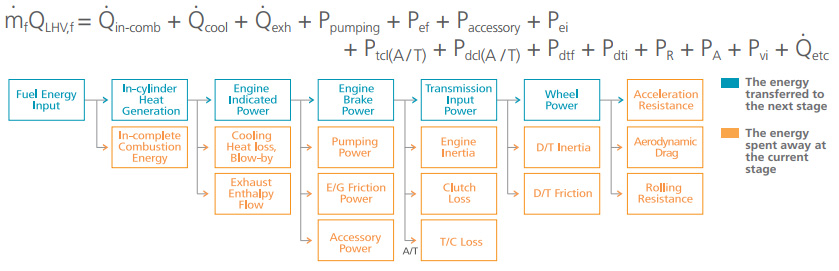

Principle of Energy Flow-Down Method

To improve fuel economy of your car, understanding of engine + T / M + vehicle interaction and control strategy (ECU, TCU) are very Important

Benets of Energy Flow-Down Method

- Energy Flow-Down Method can analyze the fuel consumption and contribution of each component and ECU / TCU control data through systematic approach.

- Client can have the whole view for the quantitative fuel consumption and contribution of each component.

- Client can recognize the weak and strong points against target vehicle.

- Client can understand how top maker optimizes every component and control data to improve fuel economy.

- Client can make catch-up plan of short, mid, long term in the most efcient cost.

How we do,

What you can get!

Measurement items

- Combustion pressure

- Ignition signal

- Engine speed

- Vehicle speed

- Manifold absolute pressure

- Air / Fuel ratio

- Battery voltage & current

- Alternator current

- Cooling fan current

- Brake pedal signal

- Accelerator pedal signal

- Throttle angle signal

- Coolant temperature

- Engine oil temperature

- Injection pulse

- Fuel rail pressure

- Fuel temperature

- Exhaust gas temperature

- Turbine rpm

- Output shaft rpm

- Engine inertia @ lift

- Drivetrain friction @ lift

- Drivetrain inertia @ lift

- Engine friction @ bench

-

Torque converter

characteristics @ MAD - Injector characteristics @ rig

- Power steering friction @ rig

-

Each gear driving resistance

@ test load (if necessary) - Shift pattern & lockup area @ MAD

Results

- Indicated thermal efficiency

- Incomplete combustion loss

- Pumping loss

- Engine friction loss

- Alternator loss

- Power steering loss

- Engine inertia loss

- Torque converter base loss

- Torque converter slip loss

- Braking loss

- Drive train friction loss

- Drive train inertia loss

- Clutch loss

- Vehicle inertia loss

- Rolling resistance loss (f0)

- Aerodynamic resistance loss (f2)

- Pilot / Main injection timing (diesel)

- Spark timing (gasoline)

- Idle RPM

- Total fuel cut time

- Total cycle number

- Cooling fan loss

- Total part load full lockup time

- Part load speed ratio distribution

- Total driving time at each gear

- Shift pattern

- Energy management system logic

- Neutral control logic

- Deceleration lockup logic

- Ne elevation logic

Recommendation

- Logic & calibration strategy

-

Engine hardware strategy

- Friction improvement

-

System application strategy

(Intake CVVT, Dual CVVT, Turbo, GDI, etc.)

-

Characteristic of engine

(BSFC, mechanical friction, pumping friction, engine inertia) - Transmission hardware strategy

- Shift pattern & lockup zone strategy

- Torque converter selection strategy

- Gear ratio selection strategy

-

Transmission related loss

(Drivetrain friction loss, slip loss, fuel consumption at each gear) - Vehicle thermal management strategy

- Vehicel electrical load strategy

- Vehicle energy save strategy

- Rolling resistance reduction strategy

- Aerodynamic resistance reduction strategy