Page navigation

Concept design using vehicle system simulation : BEV / FCEV / Hybrid ICE

Work flow of development

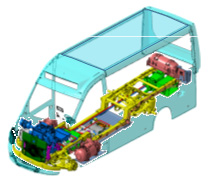

1. Packaging Design

- FC/PE system

- FC/PE Cooling system

- H2 supply system

- Wire harness

- HVCU

- Energy flow display

2. System Evaluation

-

FC system

- Performance

- Efficiency - HVCU control unit inspection test

- Battery/PE system

3. Proto vehicle development

- Repainting

- Disassembly

- Components installation

- Filling hydrogen

4. Proto vehicle test

-

Calibration

- Driving control

- Power control -

Test

- Fuel economy test

- Drivability test

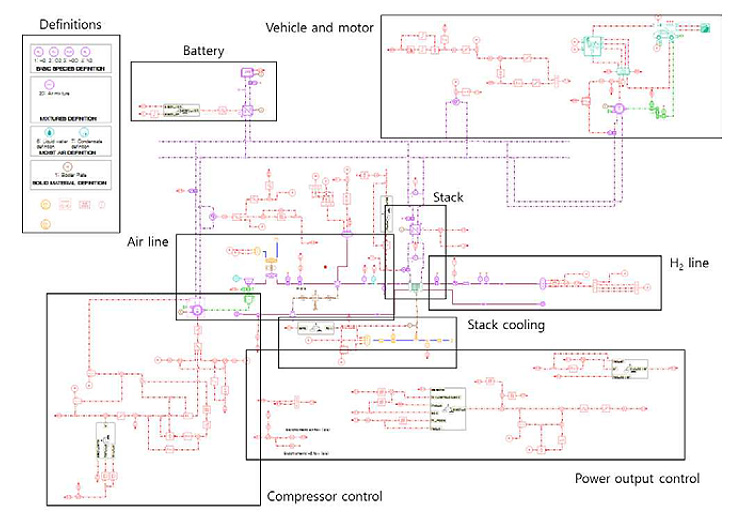

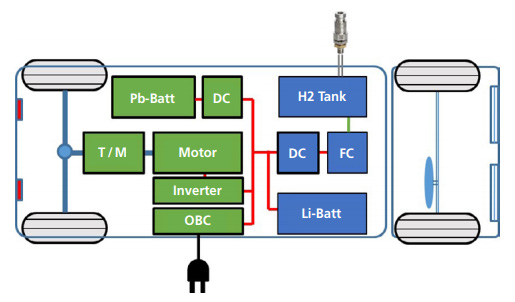

FCEV develop.

Tenergy solution :COC (Constant Output Control) fuel cell hybrid system

High vehicle system efficiency,

Low FC degradation.

| Hyundai [Nexo] | TOYOTA [SORA] | TENERGY (COC FC system) | Remark | |

| Motor | 120kW | 226kW | 100kW | - |

| Battery | 1.6kWh | 7.5kWh | 24kWh | QC, OBC charge |

| FC system | 95kW | 228kW | 30kW | High effi. const. output |

| H2 tank | 157L | 600L | 153L (6.0kg) | 700bar, Type 4 |

| HEV type | Full FC type | COC type | - | |

| Pros. | Low weight | High effi., FC low degradation | - | |

| Cons. | Low effi., FC degradation | High weight | - |

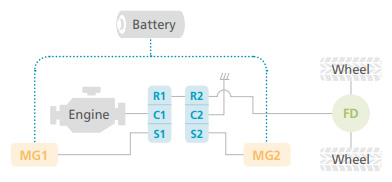

HEV develop.

Tenergy solution :Series and parallel multi mode system.

▶ Simple structure, High performance

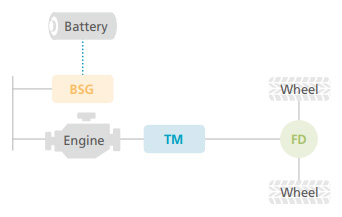

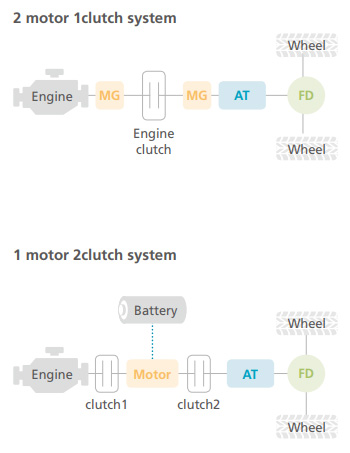

Parallel

| Architecture | OEM | ||

| P0 / P1 |  |

|

|

| P2 |  |

|

|

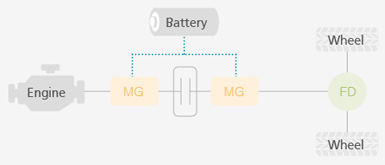

Multi Mode

| Architecture | OEM | ||

| Power-split / Parallel / Series |  |

|

|

| Series+ Parallel |  |

|

|

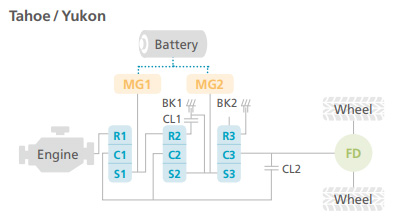

Power-split

| Architecture | OEM | |

|

|

|

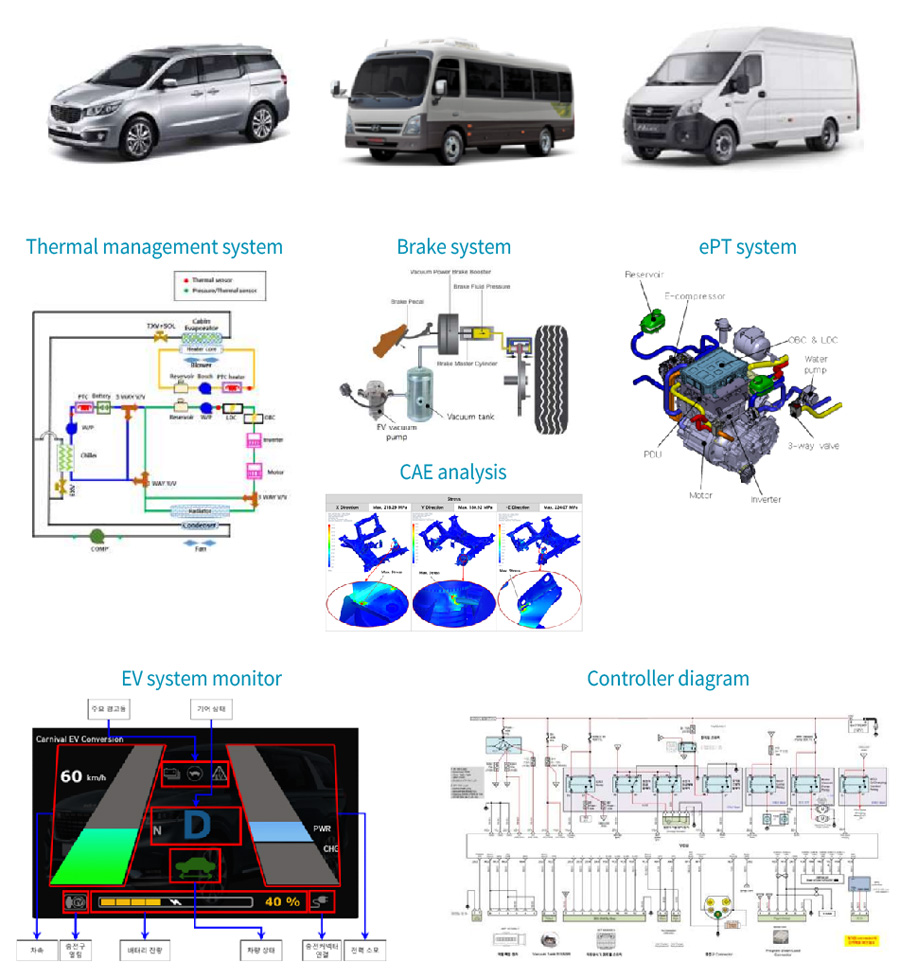

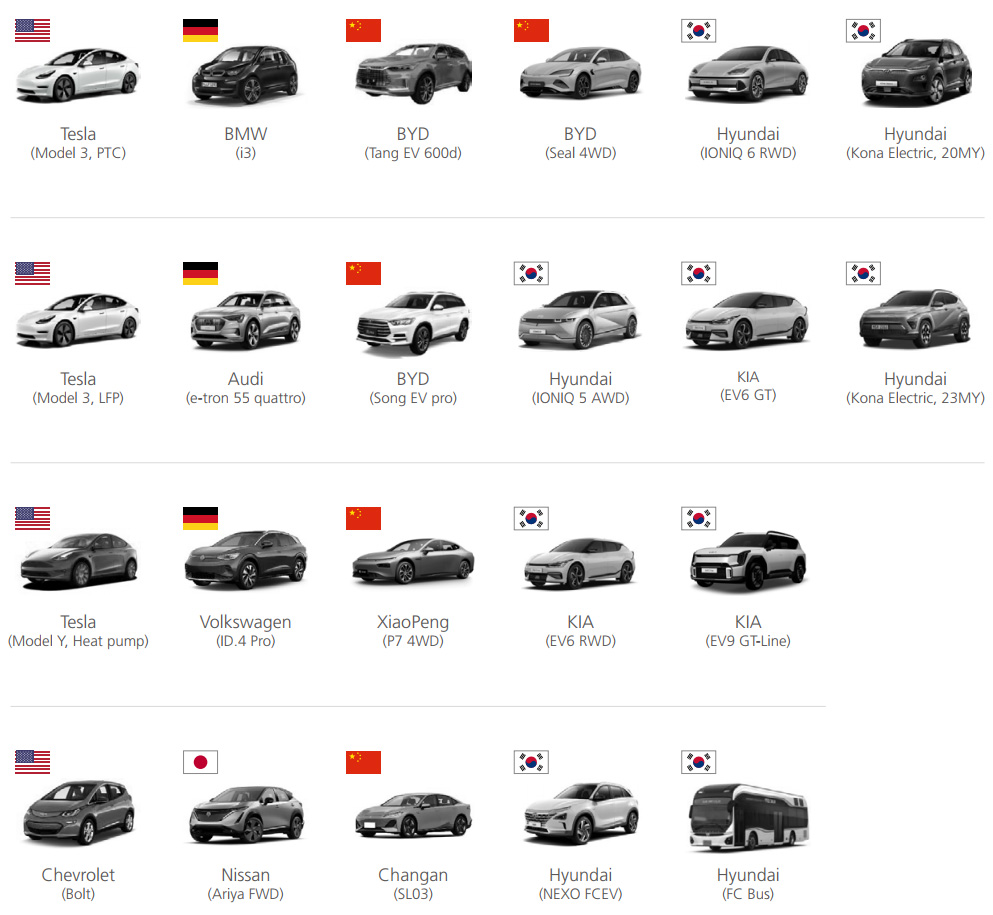

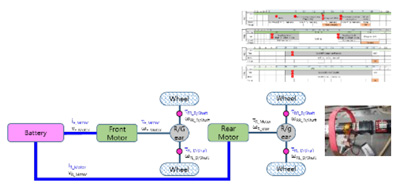

EV develop.

Tenergy solution :EV Conversion from ICE vehicle

Development of EV systems (TMS, ePT, Monitor, Controller, etc.)

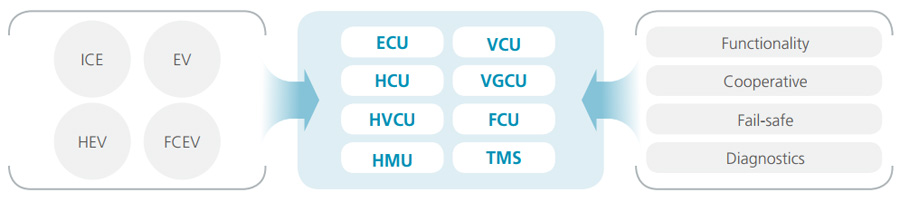

Controller develop.

Expertise in custom crafting powertrain controllers for diverse vehicle types

- Specialized feature implementation for Conventional Vehicle, EV, HEV and FCEV

- Cooperative control with ECUs

- Considering fail-safe operation

- Employing diagnostic strategies

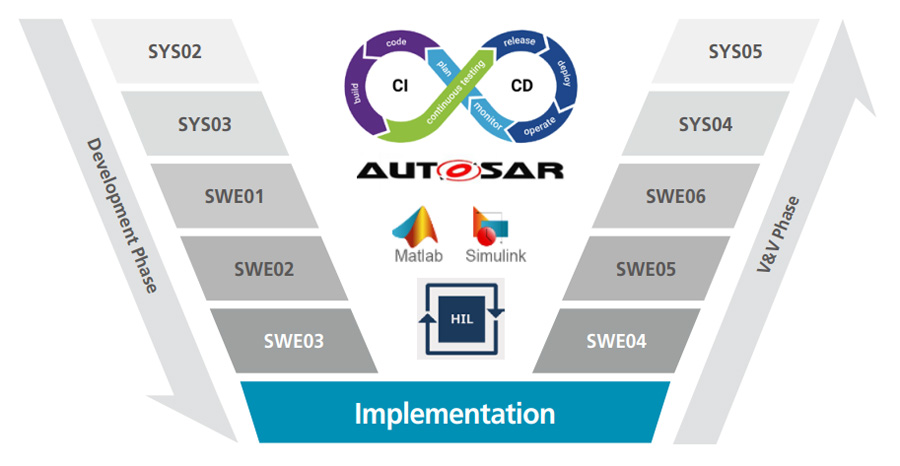

Automotive V-Model Process to design systematic development of software & system

- Adopting AUTOSAR to enhance standardization, compatibility and reliability

- Implementing Continuous Integration and Continuous Deployment (CI / CD)

- Leveraging Model-Based Design (MBD) for improved system design and testing

- Integrating Hardware-In-the-Loop Simulation for real-time testing and validation

Overview

1. Literature Survey

- Patent

- Maintenance manual

- BM video

- Public articles

2. Data Acquisition and Test Design

- CAN reverse engineering

- Installing sensor

- Design test schedule

3. Vehicle Test

- Coast down test

- Chassis-dyno test

- Real driving test

4. Vehicle Control Strategy Analysis

- Analysis system

- Analysis test results

- Analysis control strategy

Vehicle test

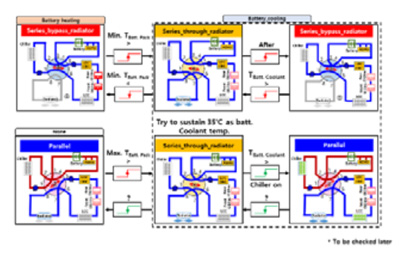

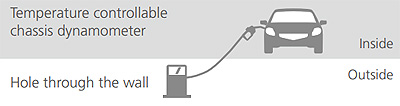

Chassis dynamometer test

- Simulate real road driving

Driving, slope climbing & charging - Operating range: -20℃ ~ 55℃

Charging

Wheel dynamometer test

-

Direct measurement of PT output

Performance

Efficiency

Cold chamber test

-

Operation range: -30℃ ~ 0℃

Thermal management

Battery charging

EV Charger(~100kW)