Page navigation

TENERGY's Vehicle Engineering division offers a comprehensive range of engineering services for vehicle development, encompassing everything from initial vehicle design to the development of various production equipment. Leveraging our extensive engineering expertise and robust program management capabilities, we are committed to providing exceptional support throughout the entire vehicle development process. The distinguished vehicle engineering capabilities of TENERGY are designed to guarantee the success of our customers. vehicle launches.

Vehicle design & validation

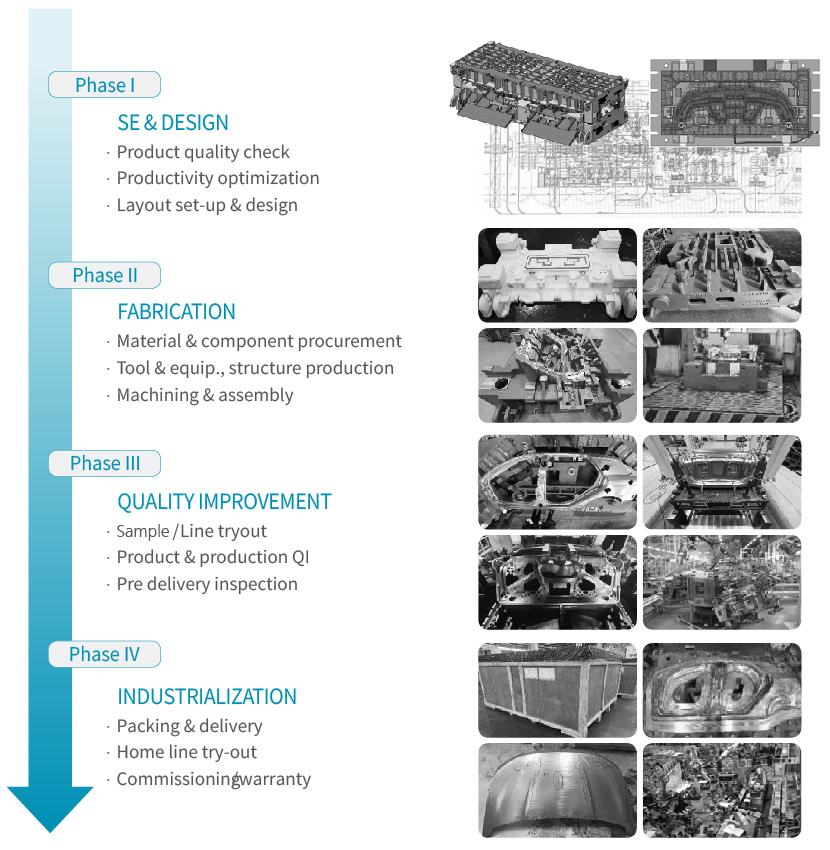

TENERGY comprehensively addresses the entire spectrum of vehicle design and validation, including the development of prototypes for testing and validation purposes. Through seamless collaboration with Styling, Manufacturing Engineering, and Powertrain Engineering, TENERGY is dedicated to crafting vehicles that stand out in terms of performance, cost-effectiveness, fuel efficiency and other critical parameters. Our integrated approach ensures the development of competitive vehicles that meet and exceed expectations.

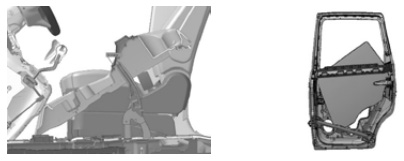

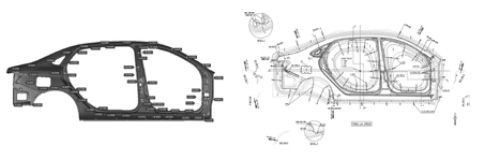

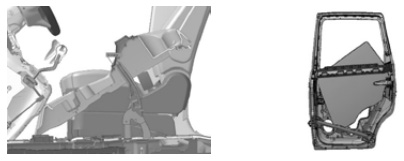

Body design

- Body structure & BIW

- Exterior trim

- Door & moving

Interior design

- IP & console

- Interior trim & HVAC

- Seat & restraints

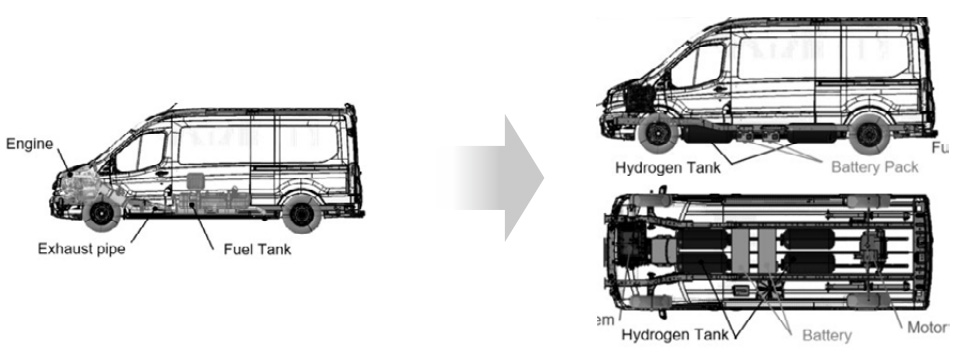

Chassis design

- Front & rear suspension

- Brake & steering system

- Heat & fluid

Electrical design

- Lamp & switch

- Wiring harness

- Electric & electronics

Vehicle package

- Layout & key dimension

- Ergonomics & legal

- Digital mock-up

Eng. Management

- Cost / Weight management

- Issue troubleshooting

- Design qualification

Prototype for T&D

- Proto BIW / Vehicle

- Mule car & cubic Jig

- Off-tool prototype

Test & validation

- Test support

- Validation (Virtual / Real)

- Homologation support

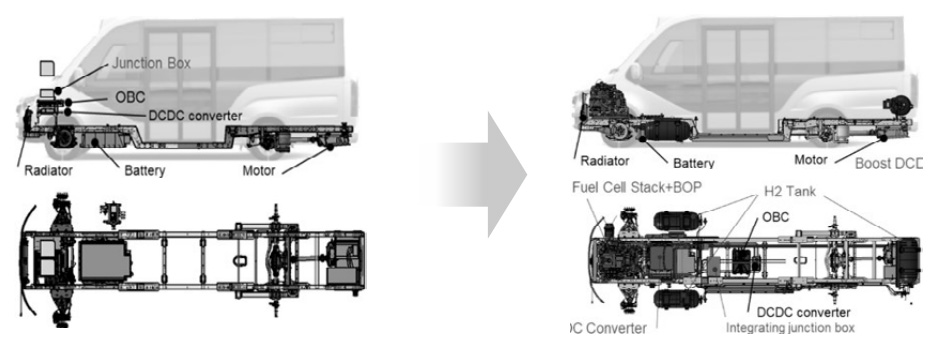

xEV Conversion design

- Package design

- System evaluation

- xEV Component development

- Prototype vehicle test and development

EV to FCEV

ICEV to FCEV

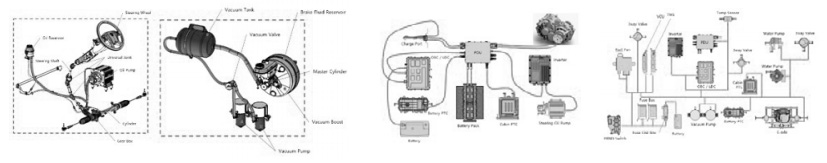

H2 storage & control system design

- Package & detail design

- Prototype system test & development

ME (Manufacturing Engineering)

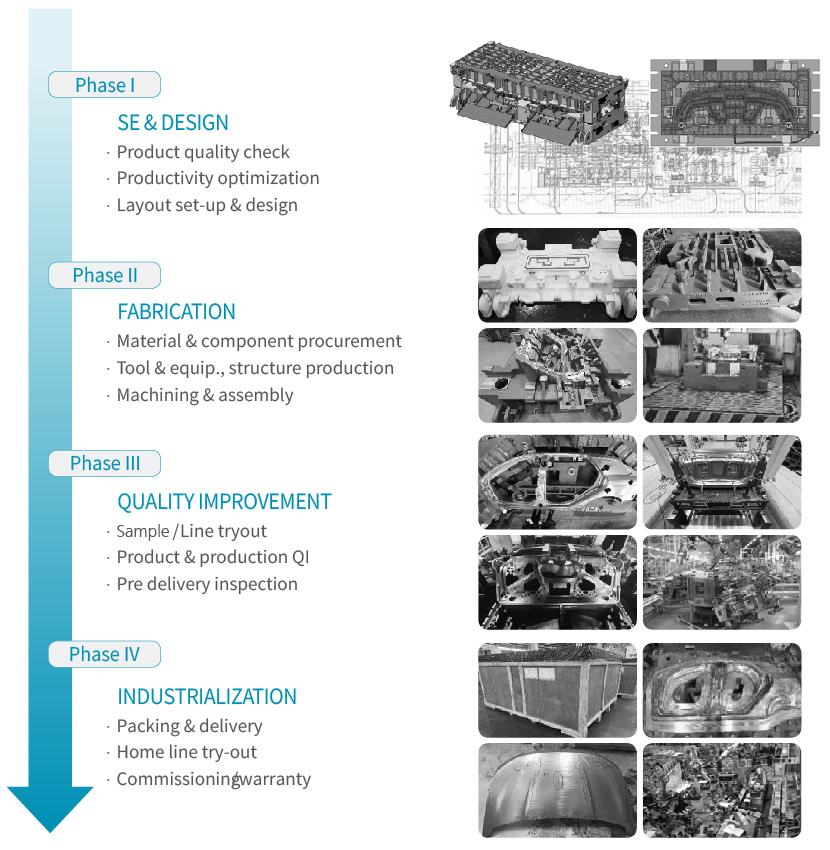

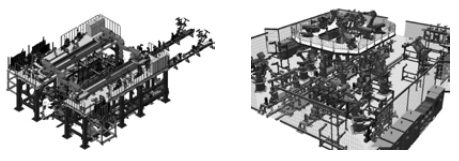

TENERGY Manufacturing Engineering (ME) provides Press Dies, Body Assembly equipment, General Assembly equipment, and Injection Mold for automobile production. Leveraging TENERGY's high-level engineering capabilities and excellent project management, we successfully supply high-quality manufacturing tool and equipment and its production output executing from initial Advanced Engineering to the Installation and stabilization of customer production plant within the desired schedule.

SE (Simultaneous Engineering)

As major virtual validation together with Computer-Aided Engineering (CAE), TENERGY provides its Simultaneous Engineering (SE) services, leveraging our comprehensive engineering capabilities that span the entirety of vehicle manufacturing. Through this Simultaneous Engineering approach, TENERGY contributes to the development of optimal vehicle designs tailored for good product quality and efficient production. Additionally, we offer expert guidance in formulating process plans that maximize productivity through optimization.

Press SE

- Panel formability & matching

- Blank material optimization

- Press mc study & process planning

- Panel quality check

- Spring-back simulation

- Product design change proposal

Body SE

- Weldability & gun access

- Line automation & duct location

- MCP / MCS & tolerance

- Cycle time

- Process flow

Paint SE

- Anti-corrosion

- ELPO access & fluid drainage

- Dipping & oven

- Water & dust proof

General assembly SE

- Assembly tolerance

- Line balance & logistics

- Workability & tool access

- Visibility, handling & error proof

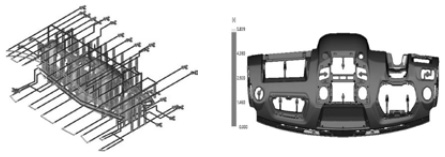

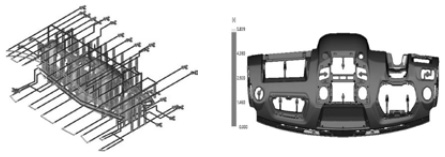

Injection SE

- Gate & hot runner position study

- Raw material flow

- Production condition

- Plastic formability

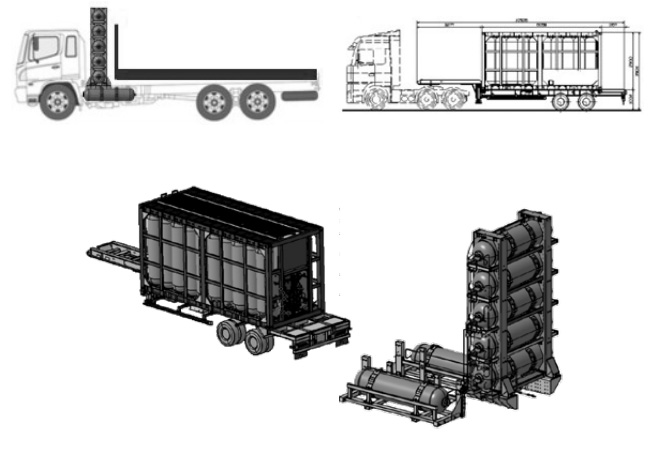

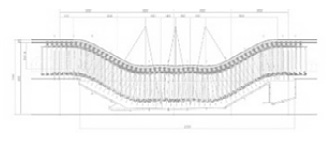

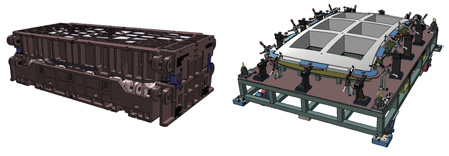

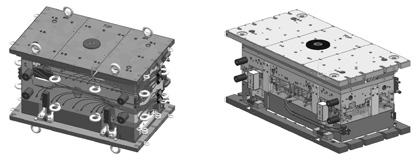

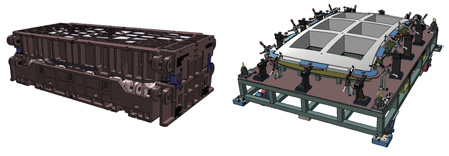

Tool & Equipment development

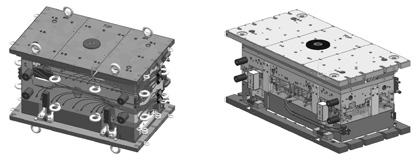

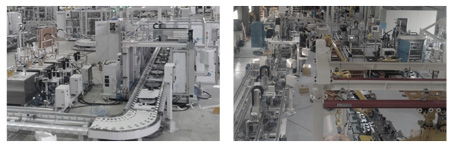

Through our Simultaneous Engineering (SE) expertise, TENERGY extends its services to encompass the development of Tools and Equipment for vehicle production. Our engineering capabilities play a pivotal role throughout the entire lifecycle of tool and equipment development, from initial design to the successful installation and commissioning phase for various aspects of the vehicle manufacturing process. TENERGY is committed to delivering top-notch quality in tools and equipment, ensuring that we meet and exceed our customers' expectations within the specified timeframe.

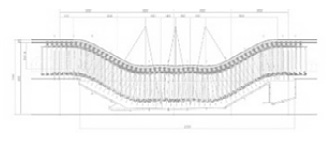

Press Die Development

- Press die

- Checking fixture

- Automation equipment

- Hemming die

- HPF (hot press forming) die

Injection Mold Development

- Injection mold

- Checking fixture

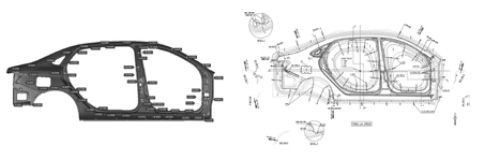

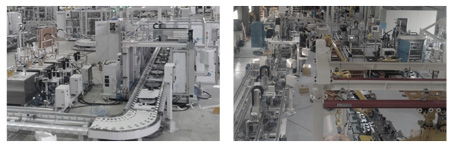

Body Assembly Equipment

- Welding jig & fixture

- Moving system (conveyor etc.)

- Welding robot system

- Hemming equipment

General Assembly Equipment

- Moving system (conveyor etc.)

- Palette & AS / RS

- Automation line

Integrated engineering

TENERGY VE provides the Integrated Engineering solutions to customers based on engineering expertise across all fields of Automotive Engineering. Through this Integrated Engineering approach, effective solutions for issues that may arise from conflicts between various areas of automotive development and manufacturing can be efficiently provided. This enables swift and optimal decision-making. TENERGY has successfully achieved positive outcomes in various projects leveraging these integrated engineering capabilities.

- Body integration : Body design + Press die + Body assembly

- Plastic integration : In / Exterior design + Injection mold

LADA VESTA SW / CROSS

Body integration

- Body design

- Press die

- In / Exterior design

- Injection mold

HEXA

Body integration

- Body design

- Press die

- In / Exterior design

- Injection mold

GAZELLE NEXT CABIN

Body integration

- Body design

- Press die

- Body assembly

GAZELLE NEXT VAN

Body integration

- Body design

- Press die

- Body assembly

SOBOL NN

Body integration

- Body design

- Press die

- Body assembly